Turning the Tide on Plastics

This week, the Naked Scientists probe the plastic problem: can science help turn the tide on our rising consumption? Plus, the killer whale that can "talk", and some groundbreaking research reveals why the USA is experiencing shakeups.

In this episode

01:09 - Conflict preventing polio eradication

Conflict preventing polio eradication

with Amol Verma, University of Toronto

For a long time the World Health Organisation have been trying to eradicate polio and in the last decade they've got to within a whisker of making it happen; but the infection is still stubbornly lurking in just three countries. So why is this end-game playing out for so long? The countries in question have had recurring conflicts and wars, which people have suggested could hamper vaccination efforts and allow the disease to bounce back. But there was no evidence to support this claim. Now there is, as Chris Smith heard from Amol Verma…

Amol - Polio is a virus that’s transmitted between humans and it causes paralysis. There was a time in the world where there were 350,000 cases of paralysis related to polio virus infection every year. Effective polio vaccine was developed in the middle of the 1900s and was released to incredible fanfare with press releases and media attention. It was a huge celebrated event for humanity that they had a vaccine.

Chris - This should be, in theory, an eradicable disease shouldn’t it? It should be possible to wipe polio out?

Amol - Yeah well, in theory we should be able to delivery this effective vaccine to enough people that would interrupt the transmission of the virus between one human to another and then the virus has nowhere else to go. It has nowhere else to live and, in theory, it could be wiped off the face of the Earth. Overall, the efforts been remarkably successful so 99.9% of the world’s polio cases no longer occur. We are now running into the last stretch, the last mile of the eradication effort. There are only three countries that have not yet eradicated polio - Nigeria, Pakistan and Afghanistan.

Chris - What’s stopping us getting this thing over the line?

Amol - There are many challenges, logistical and otherwise, to eradicating polio from these regions but one of the barriers that has often been cited is the effect of insecurity or conflict.

Chris - Why should that make a difference to the process in these places?

Amol - It may make it more difficult to deliver vaccine supplies. It may make it difficult to establish trusting relationships and partnerships with communities. It may induce mass migration, so when you have moving populations that could make it harder to vaccinate people.

The theory that our study investigated is whether insecurity makes it more difficult for vaccinators to access the children who need to be vaccinated and, indeed, we found that that was the most important problem.

Chris - How did you you do this; where did you do it and what did you actually do to find that out?

Amol - We examined polio vaccination efforts and polio cases in North West Pakistan. That’s the region of pakistan that borders Afghanistan and has been troubled by conflict and its one of the most important remaining reservoirs of polio in the world. We linked publically available data about conflict related security incidents with data about vaccination coverage and vaccination rates, as well as data about the number of polio cases in that region.

Chris - So you’re looking for an association: if there is some kind of instability or some kind of conflict in this area, is that reflected in a change in vaccination uptake and then the knock-on effect, is there an uptick in the number of polio cases off the back of that?

Amol - Yeah, exactly right. We found a 73% increase in the number of polio cases, and we also found about a 5% reduction in vaccination rates when there was high insecurity.

Chris - Given what you have found, and this does chime very much with what people had been saying is probably what’s going on for a long time, they just couldn’t prove it, now that you can actually hold up this data as objective evidence that this is what’s going on, what can we do about it?

Amol - This does highlight three strategies that could be used. The first is efforts need to be agile and nimble to respond to unpredictable changes in access to vulnerable populations.

The second is that efforts tend to be more effective if you develop trusting relationships with local communities, and so working in in that regard to engage local workers can be effective, and that’s something that the polio eradication initiative in Pakistan has made heroic efforts, really remarkable work in that regard.

The third is to design strategies that can take advantage of narrow windows of opportunity. So design programmes that if you get in, have a narrow opportunity to deliver vaccinations, you deliver a vaccine that is effective in one dose rather than three doses, and that’s the kind of thing that has been introduced in Pakistan with a new injectable vaccine rather than an oral vaccine.

06:10 - Gene sequencer the size of an apple

Gene sequencer the size of an apple

with Matt Loose, University of Nottingham

The human genome project, which was completed in 2003, was an international collaboration to read the entire genetic code - or sequence - of the human genome - the DNA recipe that makes you you. It ultimately took over 13 years, cost billions of Pounds and involved warehouse-scale buildings full of car-sized sequencing machines to do it. A third of the work was completed down the road from where we are at the Sanger Institute near Cambridge. Since those days, sequencing technology has come on leaps and bounds, and this week scientists announced that they’ve achieved the same feat - sequencing a whole human genome - but this time with a machine smaller than a chocolate bar. It took weeks, rather than years, and cost only about a thousand pounds. Lewis Thomson has been hearing how…

Lewis - Inside each of your cells a huge amount of DNA is tightly wrapped up. In fact, if all of the DNA from just one cell was stretched out, it would be about two metres long even though it fits inside a space just a hundreth of a millimetre across.

This DNA in its entirety is called your genome and it’s made up of lots of smaller subunits called bases - As, Ts, Cs, and Gs. The human genome is three billion bases long and the sequence of these bases is what determines the function of each gene - a bit like a computer code.

Being able to sequence a genome quickly and at low cost could affect how disease is diagnosed and treated, and this possibility is now one step closer. Matt Loose from the University of Nottingham told me more…

Matt - The goal of this project was to really try and push the boundaries of DNA sequencing on a new technology which is the Oxford Nanopore minION Sequencer. This sequencer was introduced about four years ago now, and it became clear around a year ago that it would be possible to sequence a human genome one a minION sequencer. The thing that’s remarkable about that is that the sequencer itself is about the size of a chocolate bar or a small mobile phone. It’s an extremely portable device and you just plug it into a laptop and you can sequence DNA anywhere that you want to.

Lewis - Most genome sequences used today by scientists are extremely large expensive machines which require specialist training. The minION sequencer is much smaller and cheaper. But how does it work?

Matt - Essentially, it’s a rectangular metal box. It has a cartridge that slips inside it and that cartridge or flow cell, as we call it, contains a membrane and in that membrane are lots of nanopores, and nanopores are essentially small holes. The way the sequencer works is it applies a voltage across the surface of the membrane, that allows a current to flow through those small holes. Also, DNA can pass through those holes and as the DNA passes through the hole it of course blocks, and changes, and alters the current flow. It turns out that the changes in current flow are proportional to the sequence that’s present in the nanopore at that moment in time. So, effectively what you get is a current trace, or we call it a squiggle, which reflects the underlying As, Ts, Gs, and Cs.

Lewis - For several years, the minION sequencer was much less accurate than the large sequencing machines used by most scientists. However, the technology has now improved to the point of being almost as accurate and, in addition to its size and cost, it has other benefits. Many current methods involve cutting the DNA sample up into tiny fragments of just a few hundred bases to be sequenced. A computer then has to the assemble these short sequences together to make the full genome sequence. This takes a great deal of time and can also lead to inaccuracies. The minION sequencer has a much higher read length - in other words it can sequence much longer fragments of DNA - fragments which are hundreds of thousands of bases long.

Matt - The advantage of this technology over other competing technologies essentially is the read length that you can generate, plus the real time nature that you can look at the sequence. So with respect to the read length, we can see parts of the genome that we haven’t been able to see before. Things like telomeres: the ends of chromosomes which can be absolutely critical in understanding particular tumour types.

I think the other issue is in nanopore sequencing, in principle, you can start looking at the sequences the moment they appear from the sequencer. So if you were looking for a particular bacteria or detecting a virus, you can see that the moment that it appears in the sequencer. There are lots of examples of people taking nanopore sequencers into the field; some of my co-authors were involved in sequencing Ebola during the outbreak. They went on to sequence Zika virus during the recent outbreak in Brazil and others are applying this technology in similar situations around the world to get real time, rapid information about the pathogens in the environment and about their sequences.

Lewis - So maybe in the future doctors could use this handheld sequencing technology to diagnose illnesses, whether that’s identifying the genome of a particular virus or bacterium or even sequencing a cancer tumour to work out which treatment would be the most effective. Thirty years ago, this would have been impossible. Now, it’s looking more and more likely.

11:50 - Down to Earth: Space plasma drills

Down to Earth: Space plasma drills

with Dr Stuart Higgins, University College London

Stuart Higgins has been drilling into this mystery, in Down to Earth...

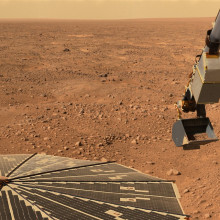

Stuart - This episode: how a space plasma drill being developed for Mars has already led to a more portable and efficient electric vehicle charger for use in the home.

Is there life on Mars? If there is it may well be hiding below the surface and Scientists from the European Space Energy (ESA) want to dig into the red planet on future missions to see what they can find. However, drilling deep underground is hard enough on Earth, let alone on another planet. ESA has funded a Norwegian company to study a new drilling technique called plasma channel drilling which they hope will allow more efficient and deeper drilling on Mars.

Plasma channel drilling was first developed by researchers at the University of Strathclyde in Glasgow. It works by placing two metal plates on the surface of a piece of rock and applying a very short, but very high power, pulse of electricity between them. The voltage between the metal plates can reach up to 50,000 volts with a peak power of 100 megawatts. That’s the equivalent of a million 100 watt light bulbs, albeit for less than 50,000th of a second.

The drill head is surrounded by water and, as the voltage quickly ramps up, something unusual happens. Rather than the electrical current taking a shortcut through the water, it turns out that under these extreme conditions the rock provides less electrical resistance - a plasma channel is formed in the rock. The electrical current can pass through this plasma, heating and expanding it rapidly to cause the rock to break up apart.

After the researchers licensed out this technology, it was eventually picked up by a Norwegian company who are now aiming to turn it into a viable space plasma drill for future missions. The key to the effectiveness of the plasma drill is its power supply which needs to rapidly produce pulses of high voltage. Room and available power are always limited onboard spacecraft so this forced the company to develop a new form of electrical transformer. A transformer is, essentially, two coils of wire wrapped around a common metal core and it’s used to turn low voltages into high ones and visa versa.

The Norwegian company developed a new transformer design that both generates higher voltages and is also extremely compact. In doing so, they realised that the same technology could be used to improve the way electric vehicles are charged at home. The company could produce the size of a home car charger, which is effectively a giant phone charger for your car, from around 100 kilograms to about 2 about kilograms using the transformers it developed for space plasma drilling.

And unusually, while the technology hasn’t yet been used in space, the spinoff from it is already available to consumers back here on Earth. So that’s how developing a space plasma drill for Mars helped lead to portable home chargers for electric vehicles.

14:46 - Groundbreaking: Earthquakes and oil extraction

Groundbreaking: Earthquakes and oil extraction

with Tom Gernon, Southampton University

In recent years Oklahoma City has been subjected to hundreds of earthquakes. A decade or so ago though it was recording only one or two. Why? The answer, a new study suggests, is that it’s down to the oil and gas industry. Contaminated water that’s been used to force out oil under pressure from below ground is being disposed of by injecting it back deep into the bedrock where it’s causing things to slip and slide about. Izzie Clarke...

Izzie - Oklahoma: a state that’s home to four million people, where the voicemail was invented and, in the 20th century, produced the most oil of any state or territory in the United States. In fact, oil was first discovered there by accident in 1859 but now, they’ve got another accident on their hands that’s shaking things up…

Tom - My name is Tom Gernon and I’m an Associate Professor in Earth Sciences at the University of Southampton.

Oklahoma has experienced some pretty intense seismicity over the last decade. Seismicity is the frequency at which earthquakes repeat through time and, in the case of Oklahoma, if you think back to 2008, they had one earthquake which was over magnitude three - by definition, an earthquake that you can feel. In 2015, the number of earthquakes was 903, so that just gives you some sense of the scale of the problem here. These earthquakes are linked to the injection of water underground into deep rock formations.

Izzie - The reason for this process is to extract oil from the ground. Across Oklahoma there are 10,000 or so wells where water is injected at high pressure deep underground to help release oil and gas which is locked up in the rocks. This contaminated water and oil combination then comes back out of the well, is separated and yes, the oil companies have their oil... but what about all that waste water?

Tom - If you think about it, you’ve got 2.3 billion barrels of waste water and you’re in a sort of landlocked state in the centre of the US. Very expensive to ship it elsewhere to be processed and treated and disposed of, so it’s economically more efficient to inject this deep underground because it’s otherwise very expensive to get rid of.

Izzie - This constant cycle of injecting wastewater into the ground not only weakens the rocks but acts as a lubricant, which is part of the problem. The University of Bristol and Southampton University developed a statistical model that was able to analyse a combination of impacting factors…

Tom - What we looked at was data from these injection wells: the injection volumes, injection depths, and injection locations through time. We looked at all these different parameters and the correlation between those different parameters and the seismicity - the earthquakes that are happening - within a given radius of the injection wells. And, I should say, typically the injection depth is about one or two kilometres beneath the surface.

Izzie - The injection depth a few kilometres underground was a huge factor for the frequencies of these earthquakes due to the type of rock lying there…

Tom - The wastewater is normally injected into sedimentary rocks which are overlying much deeper crystalline, very old rocks - you can think of granite maybe, or metamorphic rocks which are heavily fractured and so on. Liquids can then find a way downwards basically into the boundary between these two different rock types, and we know that most of the earthquakes in Oklahoma are happening in these deep, what’s called crystalline basement rocks. These are, presumably, very heavily fractured; there’s lots of old ancient faults in there which allows the stress to build up and release.

We have most of the biggest earthquakes which have happened over the past decade have actually been in this rock. The closer you inject to that level, the more earthquakes you’re going to experience. This is incredibly important; it’s not been shown before; it carries a lot of implications for regulation in Oklahoma, and potentially elsewhere. The operators could use this information to change their practices and, potentially, raise well levels to reduce the earthquakes that are happening.

Izzie - Another key finding was that there’s even a time lag. Wastewater would injected into the ground and the resulting earthquake would then hit a few months or even years afterwards. With over two billion barrels of wastewater injected into the ground every year, for Oklahoma worse may be yet to come…

Tom - Another thing we need to consider is that the oil demand hasn’t really been very high over the last two years. The number of earthquakes has dropped slightly since 2015, although we have had some of the biggest earthquakes - I think magnitude 5.8 Pawnee earthquake which struck in September 2016. This is the largest magnitude earthquake that has ever happened in Oklahoma and this caused injury and damage to buildings. This happened at a time when injection had actually been reduced by the regulators. This shows that there are these potentially significant time lags between injection and seismicity.

Killer whale imitates human speech

with Jose Abramson, Complutense Universidad Madrid

Killer whales, or orcas, are well known to talk amongst themselves, but this week one individual was recorded mimicing human sounds. Georgia Mills has the story...

Georgia - This is Wikie. She’s the first killer whale ever to be recorded imitating human speech.

José - The point here is that we didn’t want to teach English or a language to the killer whale.

Georgia - That’s study author Jose Zamorano Abramson from the Complutense University of Madrid. So why did they do it?

José - Vocal imitation is a hallmark of human spoken language. It’s very important in the evolution of human culture. We think that studies in other species has revealed that the ability to copy sounds from other members of their own species among primates is mostly unique in humans.

Georgia - Our ability to mimic is an important part of the development of our language, but it’s largely absent in our closest cousins - apes, despite their name, can't. It is seen in a few other species - famously parrots - and in marine mammals. Killer whales are particularly interesting because scientists have seen that different groups, or pods of whales have different dialects - just like accents…

José - Most biologists think that these dialects are acquired non-genetically - they are probably by social learning.

Georgia - To test whether this really was the case, José and his team saw a 14 year old orca, Wikie, could successfully imitate new sounds either made by another killer whale, her calf Moana or by a human…

Wikie had previously been trained to imitate sounds but these ones were selected to be completely alien to her usual repertoire...

José - First we found that killer whales made recognisable copies of novel sounds of killer whales and even human sounds or words - they did it quickly, so we found they are flexible, open, vocal learners. They have the capacity for vocal learning and for vocal imitation. Our results are also remarkable if you think that there was no extensive trial and error training. The sounds were presented in the air and not in the water so it was a very artificial medium for her. Also, the sound production system greatly differs from humans’. They use another vocal structure than humans so it’s remarkable that she was capable of copying our human sounds.

Georgia - Audio analysis software was used to make sure the imitations really did match up with the target sounds, although some of them were better than others…

José - We support with these results the hypothesis that dialects of certain natural populations are learnt by imitation, which means that these dialects can be seen as vocal traditions or cultures. If they have, by vocal traditions, cultures and dialects are an important part of these traditions, dialects can also serve like a social function like accents, for example. Killer whales can differentiate where are the members of their group or from other families just by the dialects, and they can announce cooperation, for example.

Georgia - What does this mean for our own treatment of these marine mammals? José points out if they do learn socially from one another, taking a member out of a pod can be more damaging than we thought…

José - You know that if you capture a killer whale or other animals that rely on social learning and some animals are very important for their social knowledge. You can have a lot of damage if you took or you kill the animals that have the knowledge because different animals play different roles in the social structure. The same thing happens when the killer whales are in captivity, you can’t release a killer whale that is captive in the ocean because she relies on social learning. So you really need to teach that killer whale the special culture, dialects or the way they hunt, or whatever, to introduce them if it can be introduced.

26:19 - Could microbes munch our waste plastic?

Could microbes munch our waste plastic?

with Steven Lee, University of Cambridge

We all know about problematic plastic filling the oceans and destroying marine life. But what is plastic, how is it made and why does it last for so long? Plus, could we get bacteria to biodegrade it for us? Georgia Mills got the low-down from Cambridge University chemist Steven Lee...

Steven - A plastic, when chemists think of plastics, what we’re thinking about is repeat monomer units, so the word polymer you may have heard is that’s how chemist’s don’t really think about plastics. That’s essentially, a bit long chain molecule that consists of much smaller molecules linked together typically via a carbon link.

Georgia - So a monomer is like a little unit, a little pod, and then a polymer is a load of these strung together?

Steven - Exactly. Poly meaning many, and mer meaning unit, comes from the Greek polymer.

Georgia - Ah, it all makes sense. So how do you make a plastic?

Steven - There’s lots of ways to make a plastic and they have very large meanings. But I think in the general terms when people think about a plastic spade or some wrapper, the way you do that is you take a small molecule that has a carbon/carbon double bonding and you apply by various heats or chemical reactions you can encourage that to form long long chains. That typically can be done by small molecules that come from the petrochemical industry for instance.

Georgia - Why does it stick around for so long?

Steven - The reason is there’s not the traditional method for things that degrade. When we think about something’s rusting or trees or organic waste being digested, there are biological organisms that have spent billions of years evolving lots of complex pathways to be able to break those bonds. In the case of cellulose that’s a polysaccharide, that’s a polymer as well but it’s made of lots of sugar molecules. But in the case of a polymer like a plastic bag at a shopping centre, that’s typically made of polythene or polyethylene and so that’s a very different kind of chemistry - one that’s got to break a carbon/carbon bond. That’s much harder for the natural world to break down and so, unfortunately, we haven’t had the bacteria and other environments and haven’t had to time to deal with that.

Georgia - Right. Something like cellulose which is actually kind of similar to a plastic can be broken down just because it’s been around for millions of years within plants?

Steven - That’s true, it’s called a biopolymer. There’s three kinds of biopolymers, but what we’re talking about here is this unusual class which we see every day but, on the timescale of evolution is a relative newcomer and we’ve only had the first completely synthetic plastic since 1907.

Georgia - Why can’t we just recycle it? Why can’t we put it like in the opposite way through the plastic machine?

Steven - Yeah. That’s a thermodynamic answer to that. It to do with all the technology to understand why plastics don’t mix is the same chemistry and the same physics that we worked out in the industrial revolution. In fact, what it’s to do with is that if you take two compounds and try and mix them together, sometimes they mix, sometimes the dont, but polymers don’t like to do that because they don’t gain as much entropy - this term about how disordered something is. So, what that really means is because polymers don’t mix, if I just take a mixture of my compounds and just try and heat them up to kind of regenerate a big slush of plastic, it means that they all phase separate. They’re much like oil and water don’t mix, you get the same thing with plastics, so what that really means is that it’s quite difficult to separate them out in order to recycle them in a way that, for instance, aluminium or metal isn’t quite as difficult.

Georgia - I guess, quite often within the same product you have a few different types of plastic all in one place?

Steven - Absolutely. If you look very carefully on the bottom of your plastic baby or on the bottom of your bottle of diet coke, you’ll see that there’s a little mark and that terms the type of plastic. What that means is that if you have polyethylene or polythene, that’s possibly recyclable with other clumps of polythene, but it’s not if you use polymethyl methacrylate or polystyrene or any other synthetic polymer we use traditionally today.

Georgia - Could we use nature to help us then. Is there anything out there that might be able to munch away at these carbon bonds?

Steven - There’s president in the literature for various bacteria and also fungus to degrade very specific types of plastic. In biology there’s lots of ways in which we can digest plastic, but the chemistry to be able to digest these specific compounds is unusual and, therefore, doesn’t exist at lot. There absolutely could be, but we haven’t found anything yet. There have been some studies where the way people actually look for them is they look in and around plastic plants because they think if the bacteria could start eating plastic it would be a limitless source of food. It’s an all you can eat buffet of energy to the bacterium, so there is a clear push for them to be able to use it. Unfortunately, normally what happens is we have to find one, because of all the chemistry that I was talking about is very specific, it means that bacteria have to evolve different ways to be able to digest specific plastics. So you don’t get one bacteria that will eat all plastics, but there are samples of bacteria that eat very specific kinds but just not very very well at the moment.

Georgia - Very briefly, do you think we could modify something in a lab - a super bacteria - to just go into the oceans and destroy all the plastic and solve all of our problems?

Steven - Yeah. “Catch a spider to kill a fly.” It’s possible and I think loads of people are working on really interesting ways to be able to modify bacteria. We have lots and lots of genetic tools in the laboratory to be able to change bacteria to do our bidding, as it were. The trouble is is that the specificicity to be able to break this carbon/carbon bond in my plastic bag and not break the carbon bond in me is very different, and that’s the challenge going forward.

34:22 - The road to reduced landfill: paved with plastics?

The road to reduced landfill: paved with plastics?

with Toby McCartney, MacRebur

What can we do with the piles of plastic that already exist in Nature? Perhaps we could use it to solve another problem that we have. That’s what Toby McCartney is aiming to do with his company MacReber. Chris Smith hear from Toby about his possible solution.

Toby - We take waste plastics, and I think it’s important to say, waste plastics. These aren’t recyclable plastics, these are plastics that are destined for landfill. We take those and we mix them in with an asphalt mix, so a road mix, to replace part of the bitumen which is another form of carbon to make a longer lasting, sometimes stronger, sometimes more elastic road structure that doesn’t pothole as regularly.

Chris - Can you use any kind of plastic for this so it wouldn’t matter if you had a mixture?

Toby - Because of what Steven was saying there, we can’t just take any old plastic and shove it in, it has to what we call it homogenise, it has to mix in well with the remaining of the bitumen that’s in the mix so that it works together to do different things to various different roads. We basically make cakes of various different waste plastics.

Chris - Talk me through the process then. So you take some plastic, how much do you need? What do you do with it to make it road ready, and then how is it deployed in the field - or road even?

Toby - We take those plastics; some of it comes from commercial plastic, waste plastics; some of it comes from a council, so household waste. Most people see a plastic bottle just as a plastic bottle, but actually there’s four different types of polymers, four different plastics within one bottle. You have the bottle that’s made from a particular type of plastic, and then the lid that goes on that’s another type of plastic, and then the wrap that’s another type of plastic.

What we do is we separate them all out and then, as I say, like a cake mix really. In fact, we have three different cake mixes where we put those polymers back together so that they work in to replace part of the bitumen - that’s the oil base, the black stuff that you’ll see in a road. Those pellets that we produce, the cake that we produce that’s added in at the same time as the asphalt is manufactured. So the bitumens taken out and our plastic pellets are then added in.

Chris - Is a bit like biodiesel where you end up where a certain amount is the green version and then there’s some original from oil out of the ground diesel and you get a sort of a mixture, when you do this you get some bitumen with some of your new plastic?

Toby - That’s it, yeah.

Chris - What sort of ratio?

Toby - It just depends on the road type. Again, most people just look at a road and see a road but there’s various different road forms. Some has more bitumen but we replace anywhere between 5 to 20% of the bitumen content that goes into a road. A road’s mainly made up of stone, so aggregates. Maybe 90% is aggregates and then there’s sand and stuff that goes in there but, up to 10% of the content of a road is bitumen itself.

Chris - How does it perform in practice?

Toby - It’s absolutely fantastic. We’ve had trials down now all over the UK. We’re just about to launch in places like Australia. Over in Bahrain we’ve got roads down; in the GCC countries for testing. We have to meet a British and European standard and we overly meet that, so it performs much better than a standard asphalt.

Chris - In what way in terms of wearability, durability, in terms of safety? Put me through all the different parameters are that you assess it by?

Toby - We have three different products, or three different cakes. One of them gives a higher tensile strength, so it makes the road basically stronger so if you’ve got heavy good vehicles and lots of traffic on a road it’s very good to create a stronger road.

Another product adds some flexibility into the roads. Up in say Scotland, or over in Canada where we have lots of freezing conditions, what happens is as we get a lot of rain, the rain gets kind of soaked up into the asphalt and is stored in tiny little air pockets within the asphalt. As that water freezes, and we know the science behind this, that water then expands and often we’ll see on our roads lots of cracks and therefore potholes. One of our products gives and elastic quality, if you like, to the asphalt so it reduces those cracks and, therefore, reduces those potholes.

Chris - What about the environmental impact because one of the reasons people are so concerned about plastics is that where particles, ground up plastic, ends up in the ocean, it then becomes fodder for filter feeders, and it can concentrate other pollutants and things up the food chain as well as being directly toxic for marine animals, and it’s not good on land either? Is there not a danger that if you put lots of plastic on the roads that it’s going to wear down as vehicles go over the road surface and, therefore, it’ll turn into plastic particles that wash into drains and end up in the sea anyway - we’re back to square one?

Toby - Yeah, I think there’s two points here. The first is you have to remember where our plastics are coming from. They are from landfill or destined for landfill, and what happens when that goes to landfill a lot of it’s blown out into our rivers and then off into our oceans as whole plastics. Now we’re taking those plastics and we can only take the ones that homogenise into the bitumen so they become part of the bitumen that’s in the road so there’s no microbeads. You may have heard of microbeads, there’s no plastics present in the road. It becomes part of the bitumen. The roads currently, the bitumen is the binder so that’s the sticky stuff that sticks the stone together. It’s like at the moment we have pritt stick in our roads and what we produce with our asphalt manufacturers is the superglue. If anything, it stops the leaching of that bitumen going off into our rivers.

Bioplastics... from poo!

with Damian Laird, Leonie Hughes, Murdoch University

Could we switch to an alternative that isn’t so long lasting? Bioplastics aim to do this, by using alternatives to oil in the production process. One team is aiming to cut waste even further by making bioplastics from waste itself! Georgia spoke to Damian Laird at Murdoch University in Perth.

Damian - We like to tell people that we’re making plastics from poo but, in reality, what we’re trying to do is utilise resources that are in waste streams and turn them into something profitable. Rather than just basically treat them and send them out into another stream, try and make a product out of them.

Georgia - What kind of product can you make from sewage?

Damian - To be frank, we don’t quite use the sewage. We use the bacterial cultures that are in the sewage and they can produce a bioplastic. That’s biodegradable and we can use it for packaging and some other types of things and replace oil based plastics.

Georgia - Would this look like an ordinary plastic? Would it smell?

Damian - No, no, they just look like ordinary plastics at this stage. They definitely don’t smell, the cultures themselves don’t even smell which is great because it makes the lab much more interesting. But, yeah, we’re hoping that we can reproduce the same characteristics of an oil based plastic but hopefully use a biological process to get it done, so whilst the biological process is cleaning the water we’re getting a product at the same time.

Georgia - How does this technology work?

Leonie - My names Leonie Hughes and I’m a lecturer in chemistry at Murdoch University in Perth, Western Australia.

Basically, it’s the equivalent of us eating too much food and getting fat. The bacteria are put under conditions where they are given far too much food, but not enough of an oxidant source, such as oxygen or ammonia, something like that. So they get too much of chips and not enough fruit and veggies and exercise. Under those conditions they effectively store the rich carbon source that they get given so that they can hide it from other bacteria. It’s an evolutionary thing that advantages them over other bacteria. And then, under conditions where they suddenly have no external source of carbon but a rich source of oxygen or ammonia, they can then use that to continue growing when no-one else can.

Georgia - I’m imagining the bacteria equivalent of a hamster stuffing seeds in its cheeks?

Leonie - Pretty much. It actually form vacuoles in the cells that you can visualise as big lumps of plastic basically.

Georgia - What do you have to put into the bacteria to get this plastic out?

Leonie - Many many many bacteria are shown to do this, obviously some are better than others. You just need to give them something like glucose or vinegar, something rich in carbon, and let them do it. Just try not to give them too much oxygen or too much nitrogen at the same time and they pretty much go for it themselves.

Georgia - Then they create these bags of plastic in their cells, how do you then get this out of them?

Leonie - At the moment this is the un-environmentally friendly bit, potentially. This is the bit where we have to use solvents and thing to kill the bacteria and extract out the plastic, so that part of it, at the moment, is not looking particularly nice. However, there are some people doing some research in similar areas with things like algae that can extrude thing like bio oils or potentially even the plastic so there are other ways of looking at it.

Georgia - How is this plastic different from ordinary plastic?

Leonie - It’s not. It’s what’s classed as a thermoplastic. It still has the same kind of properties that plastics that you see in shampoo bottles and things have. It does need some post-processing, so it doesn’t have the cross-linking things, the more complicated third degree structure that plastics have that get used commercially. But those are things you can add in a chemical sense after they’ve been extracted from the bacteria. We might be able to design the feed that we give the bacteria better to enhance the production of copolymers, so polymers made up of more than one monomer, more than one building block and, if we do that, plastics will come out closer to commercial plastics at that point already.

Georgia - How easy will this be to scale up? How are you going to get a usable amount of plastic from this process?

Leonie - Yeah, it’s not trivial. We would have to do things like high density cell cultures and they’re quite hard to manage. You would need to have membrane technologies and things like that to have maximum, maximum, number of bacteria in small footprints of space so that you’ve got minimal amount of water, maximum amount of bacteria and, therefore, ease of extraction of the bacteria. These are not trivial questions but, if we can get the technology working at the lab scale, then that’s where we would link up with an engineer who would solve, hopefully, those problems for us.

Georgia - Then, at the end of this process you hopefully have a plastic that is biodegradable. Why is it biodegradable?

Leonie - Just purely because of the nature of why the bacteria make it. They make it so they have carbon source later when they have abundance of oxygen, but they don’t have any carbon external to the cell. It has to be degradable by them otherwise they wouldn’t have made it for the advantage of getting the fat in their cells and stealing it from other bacteria, so that automatically means it’s biodegradable.

Georgia - Best case scenario: what are you hoping that this can do?

Damian - The big picture is that we could hopefully locate one of these plants next to an industrial site, take their waste water, clean up the nitrogen in particular that comes out of it that the bacteria can use, and then also produce a product. We can hopefully create a product that we can change that product at will for different uses.

One of the really big ideas we’d like is not just to take traditional waste streams like you would expect in a wastewater treatment plant, but industrial waste streams as well. There are lots of industries - wineries for example, breweries that use use bacterial cultures to clean their water before they release it, but that contains a lot of carbon. We hope that what we can do is create carbon, create these polymers from that waste carbon in a sense, and then may be able to produce the packaging for the beer along the way.

Georgia - Using a product that would have been created anyway by this other process that would have otherwise gone to waste?

Damian - Yeah. And so that whole process them becomes very microbiological because you use yeast to make the beer in the first place. Bacteria in yeast to clean the water and then produce the packaging potentially for the product, which is amazing.

Will we solve the plastics problem?

with Steven Lee, Cambridge University and Toby McCartney, MacRebur

What are some ways we might reduce plastic use in future? Chris Smith and Georgia Mills discuss various ideas with guests Toby McCartney and Steven Lee...

Georgia - I guess throughout the show we’ve found a lot of things people are working on but there doesn’t seem to be any kind of silver bullet on the horizon here, so I suppose what I’ve learned is that I just need to reduce the amount of plastic I use. And Chris, you an me should both hang our heads in shame because we’ve both brought in plastic wrapped food!

Chris - We were discussing this before the programme because Steven, we offered him some cake and he didn’t want any, but I brought in cake of the week covered in clingfilm, Georgia turned up with brownies. Both foodstuffs are delicious but, unfortunately, they’re covered with environmentally extremely unfriendly and not on programme message coatings and packaging. It’s a classic case of do what I say, not what I do.

Georgia - Steven I’m curious, do you have any top tips on reducing our own plastic consumption?

Steven - It’s not what one would consider traditional but one way you could reduce your plastic use is to think about trying to use alternative forms of transport, things like electric cars. When we take crude oil out of the ground the majority of that oil is used to make petrol, but all of the stuff that’s left over is the feedstock for our plastics, so we can reduce our need and our demand for the petrochemical industry we're decreasing our need to be able to use this byproduct to turn it into plastic.

Georgia - That’s a really interesting point. I hadn’t really thought of that the fact that plastic is being used from a byproduct so why not turn it into something?

Steven - Absolutely.

Chris - The other point, because someone said to me the other day Steven, I don’t know what our take is on this that we should just package all these things we see in the supermarkets in paper, for example. But then I pointed out, and maybe you can tell me if I’m right, that you’ve got to factor in that if I package the foodstuff in plastic it lasts longer. It has a longer shelf life therefore we’re probably going to throw away less food, and we know that rearing meat is incredibly bad for the environment in terms of carbon emissions, transportation of the meat, disposal safely of waste food, and so on. So it’s not just as simple as what we use to package stuff up is it?

Steven - Absolutely. What you really want to think about is the total energy content so that includes everything as you say. Quite often might use their carbon footprints in a similar kind of quantity, so how much energy is required to make not just your apple but your apple packaging and put it in a truck and move it from the other side of the world. That’s the thing you want to minimise and so there’s a lot of interest into being able to use local food because what you’re doing there is reducing your energy footprint, and ultimately the goal of these things is to reduce the amount of energy required to produce these packaging materials.

Chris - Can we just bring in Toby at this point - toby from MacReber. Is this sort of analysis the kind of thing that you did when you were considering the impact of doing the impact assessment for your road surfacing project?

Toby - Yeah. We look at our business from a carbon emissions standpoint. Unfortunately, the construction industry is pretty bad for releasing carbon emissions in everything that it does.

Chris - 40% of the world’s CO2 is from concrete isn’t it?

Toby - Yeah, that’s right. We’re looking to reduce those by using less bitumen. We’ve worked out that we save a ton of carbon emissions for every ton of bitumen that we replace, which is quite hefty really.

Georgia - Steven, do you have any points on Toby’s business.

Steven - Yeah. I think the interesting point here is that I don’t think anyone is trying to reduce plastic use completely, and I think that’s an important point. There’s always going to be a need to be able to use it. It’s a wonderful material that we have and to think that it’s all bad under all conditions is wrong. I think what you want to do is think about a way to stimulate the economics of such, such that if we do really need disposable plastics that we make biodegradable plastics more economically viable in which case all of the problems will go away because people will instantly switch to these more renewable sources.

Georgia - Toby, will that spell trouble for you if you used up all the plastic in the landfill?

Toby - Unfortunately for the rest of the world if we stop producing plastic today, MacReber, we would still have enough to lay every road, every new road around the world just with the waste that we produce at the moment. So stopping it isn’t going to stop our business so we would love it to be stopped because we’re on a mission to stop the plastic epidemic as we call it, but it won’t have any impact on our business.

52:13 - Cool runnings: does sprinting or walking conserve more heat in the cold?

Cool runnings: does sprinting or walking conserve more heat in the cold?

Izzie Clarke took on Trent's cool question.

Izzie - When you go outside and stand in the cold your body is much warmer than the air around you. Because heat likes to flow from hot to cold, it warms up the air next to your skin and this creates a kind of warm air blanket that slows down further heat loss.

But, if it’s windy, or you start moving then the warmer air molecules are pushed away and you’ll be exposed to new cold air. So running means you lose more heat to the air but we all know running warms us up. The faster you go, the more heat you generate and you get to your warm cosy house much faster.

So what’s the best strategy? It turns out whilst you are generating heat when your run, the air takes away that protective layer rather quickly at slow speeds. So, if you’re not the fastest runner it’s better to walk through the cold than break into a light jog.

Now, there are a few factors to work out the minimum running speed where the heat you generate finally balances out the heat you lose due to air movement. For example, the surface area of an adult human: how much heat do they generate plus the effect of wind on heat loss, but even so, this calculation applies to heat loss of bare skin. I mean we may be the Naked Scientists but we certainly don’t advise running at -40 degrees in your birthday suit.

All jokes aside - clothing’s actually an important factor here. While running slowly through the cold air naked might get rid of your warm air blanket, if you wrap up tight your clothing will trap the warm air preventing windchill on your skin. So, to sum up, either stay put or where appropriate winter clothing, or run very very fast.

Next time, we’re simmering down to this question from Steve:

Switzerland has now banned boiling lobster live. Do they experience pain; how do we know?

Comments

Add a comment